The environmental impacts of business can be studied from various perspectives: are we interested in the emissions from a company’s own operations, land use in construction, or perhaps a precise life cycle assessment for a single product? All the topics are important, but they require very different research methods. In this blog post, we will tell how product environmental impacts can be studied with life cycle assessment (LCA) and how the findings can be effectively used for communication and minimizing the environmental burden. Dive into the world of LCA!

Framery is a Finnish, industry-leading company that produces and develops soundproof pods and workspaces. Their products can be found in 98 countries, used by leading companies globally. Framery recently announced three new products. Being committed to sustainability work, they also wanted to present science-based environmental impact calculations for these products right in the beginning. Hence, UseLess Company and Framery started their co-operation in autumn 2023.

Framery’s Sustainability Manager Noora Jukkola, the contact person in the project, says: “Framery is committed to the UN Global Compact initiative on corporate responsibility and has set greenhouse gas emission goals approved by the Science Based Targets initiative. Regarding the new products, the goal is to halve their carbon footprint by the end of year 2028 compared to the starting level calculated in this study.”

LCA widens the understanding of environmental impacts

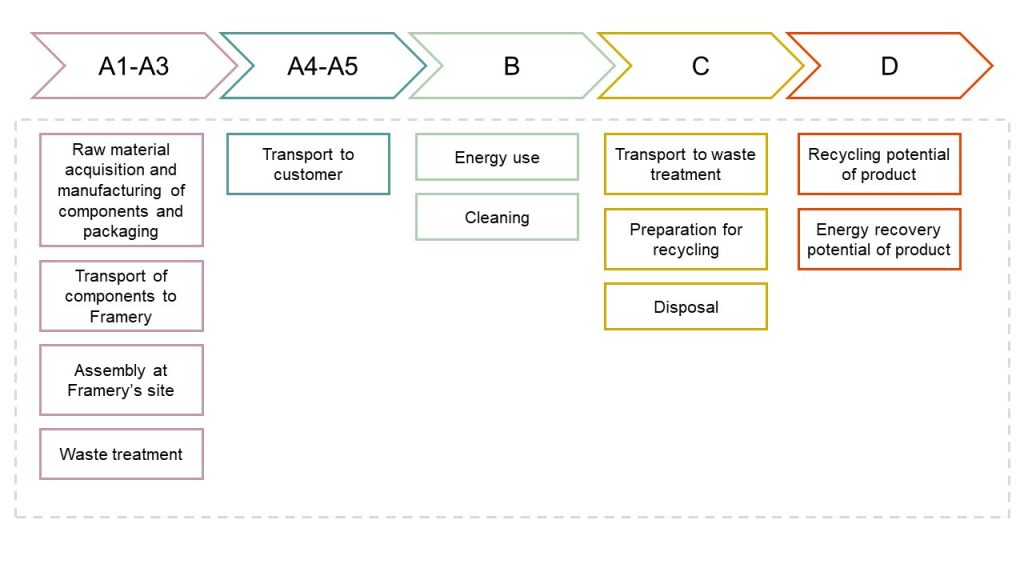

LCA is applied in many fields like research, product design, and communication. Framery products are a part of the built environment, so the goal of our project was to create usable and understandable calculations for construction and real estate industries. Various LCA methods are found in these industries, but possibly the most common method is to divide building life cycle stages into modules from A to D. The figure below illustrates Framery products’ life cycle divided into these modules.

More detailed calculation guidelines for each module are offered by the EN15804 standard and some specific product category rules (PCRs). As an end result, an environmental product declaration (EPD) is created. These somewhat consistent and third party verified EPD reports can be utilized for assessing the total environmental impacts of buildings. With this background, it was clear that the LCA of new Framery products would follow the EN15804 standard. To complement the standard, the PCRs for furniture were used.

How to create an EPD?

EPDs are based on product life cycle assessment which follows the ISO14040 and ISO14044 standards. In the beginning of our project, Framery’s production chain was examined with a life cycle inventory: what kind of materials and components are used in the pods, what happens in the supplier facilities, how Framery assembles the products, what kind of transportations are needed in the product system, where are the products used, and what happens after that? The hypothesis was that the biggest environmental impacts would occur already in the component manufacturing and pod assembly, so the most accurate process information was needed from the component suppliers and Framery’s own operations. UseLess ensured that the gathered data was consistent according to the standard and measured in the right unit for the calculations. Data collection from material suppliers may be challenging due to complex supply chains and varying possibilities to deliver the requested data, but the inventory was successfully completed with a few additional questions. The inventory included comprehensive and sufficient information on the material and energy flows throughout the life cycle, completed with assumptions guided by the standards and data from the LCA software GaBi.

Access to LCA software with broad databases was an essential part of the study because a vast amount of information is moved in complex product systems. A sensibly built life cycle model can also be updated with moderate effort if needed. Updates were required in our case project as well: the production was under development during the project, so some information was still specified along the way. Together with Sustainability Manager Jukkola, it was easy to play with the parameters, so the environmental impacts demanded in EPDs were successfully calculated. The assessed impact categories were e.g., global warming potential (also known as carbon footprint), acidification and abiotic depletion. Before EPD publication, all the calculation details were reported and sent to a third party for verification.

The LCA added value to product development

Many projects would end here, but Framery saw the wider possibilities of such calculations: based on the results, the company has prioritized emission reduction options between different components and material choices. We assisted by interpreting the results and assessing the potential impacts of certain emission reduction actions. In a follow-up project, a carbon handprint (=avoided emissions) was assessed in a situation where Framery workspaces would reduce the need of building and renovating meeting rooms. This helped in connecting the EPD results to actual office life practices.

Finally, the conclusions were clear:

- In the production phase, Framery should focus on the environmental performance of raw materials together with their suppliers.

- During the use phase, the most important factor is to enable the longest possible service life.

- A future objective is to utilize LCA further in product development so that the environmental impacts of design decisions can be understood in real time.

“Framery wanted to publish the carbon footprints immediately with the launch of the new products, responding to customer expectations as well as driving own operations towards new emission reductions. Due to the pressured schedule, we were just scaling up the production during the calculation phase which challenged the project group. Co-operation with UseLess was flexible and their solid LCA skills were just the right addition to the project”, Noora Jukkola says.

The project was rewarding and developing for us at UseLess as well since we got deeper into new kinds of product life cycles in the building and real estate industries. The best part was to see how interested Framery was in applying our work, starting from the very first interim results. We are grateful to everyone involved in the project and encourage other companies to consider LCA in sustainable product design as well!

The published EPD documents are found below:

Framery One Compact EPD

Framery Four EPD

Framery Six EPD

This was just one example of the wide range of different product LCAs. In addition to EPDs, many other types of LCA studies can also resolve the mysteries of product sustainability – both for companies and their customers. Hopefully you got interested in this topic. Feel free to contact us, we are glad to help you!

Article photo (c) Framery