Circular economy is a widely accepted concept for decreasing the consumption of natural resources and environmental impacts. Circular economy has the potential to resolve the triple planetary crises climate change, biodiversity loss and pollution. The EU is pushing transition towards circular economy with Circular Economy Action Plan, one of the main building blocks of the European Green Deal. Companies can transform their business activities to circular ones with these five recognized circular economy business models are1:

- Circular inputs

- Sharing economy concept

- Product as a service

- Product lifetime extension and

- Resource recovery.

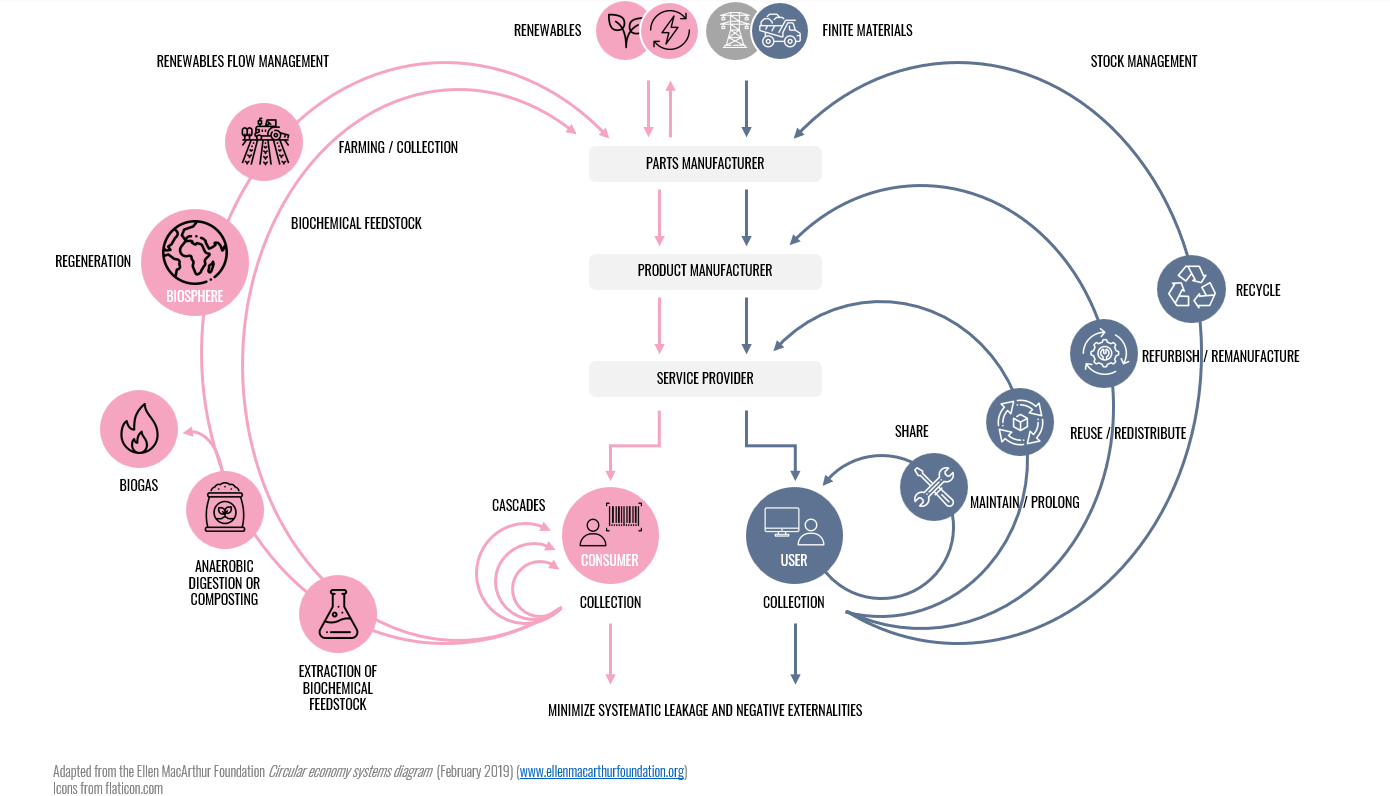

From a systems perspective, according to Ellen MacArthur Foundation, circular economy can be divided into two main cycles – the technical cycle and the biological cycle. The biological cycle is for materials that can biodegrade and safely return to earth including consumables such as food. Technical cycle is relevant for products that are used rather than consumed.

Circular products can reduce environmental impacts

With less pressure on finite materials, circular economy can reduce environmental impacts of products and services. The benefits of circular products and services should be communicated with reliable metrics. Life cycle assessment (LCA) is a science based and standardised method which can be used to calculate and communicate the environmental impacts of products and services. A common application of LCA is carbon footprint calculation, which focuses on climate impacts.

Environmental impacts can already be assessed during the product design phase. This helps in minimizing the product’s actual environmental impacts. Read how Framery used product LCA results to support their product development and more about our services to support product development.

More examples of circular economy are needed

According to The Finnish Innovation Fund Sitra, by 2030 the value added by the circular economy could be EUR 3,700 billion. Circular economy thinking can also increase the life cycle value of products by 75%, and circular business models can increase business revenues seven-fold in comparison to traditional business models.

Even though the concept of circular economy is widely known, the solid business cases are still limited especially for critical repair and remanufacturing services that extend product use states the European Environment Agency. In material use level, the circularity rate is 11.5% in Europe. The aim in EU is to double this rate between 2020 to 20302.

One example of a service supporting circular economy is modernization by ABB. ABB offers services for their customers to extend the lifetime and performance of their motors, generators and drives. UseLess Company together with ABB calculated the climate impact that can be avoided with drive modernization.

Electric drives at the core circular economy

Nearly 70% of all electrical energy in industry is used to power motors3. These motors enable multiple process applications, such as pumps moving liquid, or fans moving air. ABB’s variable speed drives control the speed of electric motors to match task in hand, increasing energy efficiency up to 80%4. Modernization service is offered to existing equipment. The benefits of modernization are extended lifetime, optimized performance, and increased energy efficiency while reducing waste.

In low-voltage drives modernization service, only the essential components of the drive are replaced and for example, existing cabinet structures can be re-used as such5. Modernization service includes four main phases:

- Manufacturing of new replacement components

- Transportation of components to customer

- Installation of new components at customer site, and

- Waste management and recycling of old components.

The climate impacts of the service were assessed based on primary data from ABB, life cycle assessment (LCA) databases and scientific literature. The study followed the guidelines of ISO14067 Carbon Footprint of Products standard6. For the modelling of transportation scenarios, representative client locations were selected around the World. The modernization service was compared to the replacement with new ABB drive with the same operational metrics.

Modernization avoids greenhouse gas emissions

According to the results, the modernization service helps to avoid up to 55% greenhouse gas emissions as compared to completely new drive replacement. The results vary depending on the customer location, chosen transportation methods and waste management practices.

The main contributors to the reduced climate impacts are:

- Reduced need for materials and components

- Lighter transportations

- Reduced amount of waste

ABB can use the results of this study in communicating the benefits of using drive modernization. The service is a great example of circular economy and can help the customers of ABB in reaching their own sustainability and climate targets. The UseLess Company team is proud of the opportunity to support ABB in communicating the benefits of their services.

About ABB

ABB is a technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. The company’s solutions connect engineering know-how and software to optimize how things are manufactured, moved, powered, and operated. Building on more than 140 years of excellence, ABB’s 105,000 employees are committed to driving innovations that accelerate industrial transformation. Read more about ABB’s services for existing equipment here.

References

- Lacy, Long, and Spindler. 2020. The Circular Economy Handbook. DOI: https://doi.org/10.1057/978-1-349-95968-6

- https://www.eea.europa.eu/en/analysis/indicators/circular-material-use-rate-in-europe

- https://new.abb.com/drives/energy-efficiency

- https://new.abb.com/motors-generators/energy-efficiency

- https://new.abb.com/service/motion/modernization-and-performance-improvement-services/drives

- https://www.iso.org/standard/71206.html